Design and manufacturing of Train Control & Monitoring Systems

Train Control & Monitoring Systems

INGESYS IC2

Rolling Stock Subsystem Controller

INGESYS DCU SIL2

Railway Door controller with SIL2 certification

INGESYS IC2

Rolling Stock Subsystem Controller

INGESYS RCM

Rolling Stock Online Monitoring & Data Logging

INGESYS ACM

Advanced Software for Analysis and Diagnostics

INGESYS SR A

Acceleration Sensors for Rolling Stock Monitoring

INGESYS IC2

Rolling Stock Subsystem Controller

INGESYS IC2

Rolling Stock Subsystem Controller

INGESYS IC2

Rolling Stock Subsystem Controller

INGESYS RCM

Rolling Stock Online Monitoring & Data Logging

INGESYS ACM

Advanced Software for Analysis and Diagnostics

INGESYS SR A

Acceleration Sensors for Rolling Stock Monitoring

INGESYS RC3 (TCMS)

Train Control & Management System

Products

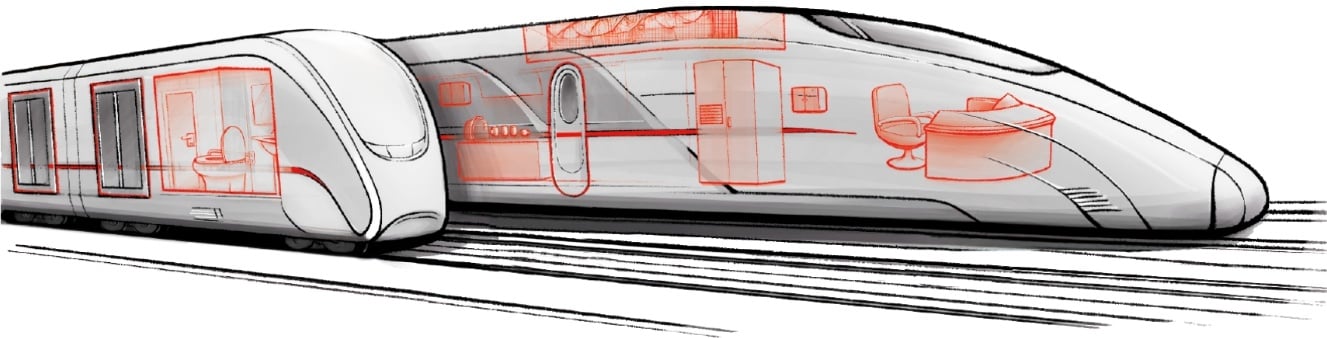

We are the only ones offering you a 360º Control and Monitoring Solution specifically designed for the railway sector. From the TCMS to the datalogger, everything you need to operate with precision and efficiency.

INGESYS RC3 (TCMS)

Train Control & Management System

Our clients

Talgo

Pesa

Turasas

Alstom

Features

- Complete range of power supply modules, processors and I/O modules

- Modular structure -19’ rack mounting

- Redundant architectures (processors, comms, power supplies)

- EN50155 & EN45545-2 compliant

- Designed in accordance with cybersecurity standards (IEC 62443)

- I/O Concentrated or Distributed topology

- 30 years supply

INGESYS IC2

Rolling Stock Subsystem Controller

Our clients

Talgo

Pesa

Alstom

Metro Sevilla

Features

- Distributed VCU

- Internally modular system customized to application requirements

- Wide range of I/Os and Communications modules (CAN, TRDP, TCP/IP, TCN, RS232/RS485, Modbus RTU / TCPIP, FTP, WebServices, SNTP ...)

- Designed in accordance with cybersecurity standards (IEC 62443) -IEC61131, “C++”, Matlab/Simulink programmable

- EN50155 & EN45545-2 compliant

- Embedded Web Server

INGESYS SR A

Acceleration Sensors for Rolling Stock Monitoring

Our clients

Wiener Linien

Alstom

Pesa

Talgo

Features

- Integrated 3-axis vibration and temperature measurements

- Technology: MEMS

- High level of electromagnetic noise immunity

- Connection length for long distances

- Advanced diagnostic functions

INGESYS ACM

Advanced Software for Analysis and Diagnostics

Our clients

Wiener Linien

Alstom

Pesa

Talgo

Features

- User customizable software

- Multi-platform and multi-browser web application

- Longer installation lifetime

- Maintenance costs reduction

- Apps can be developed by the user and be integrated in the cloud

INGESYS RCM

Rolling Stock Online Monitoring & Data Logging

Our clients

Wiener Linien

Alstom

Pesa

Talgo

Features

- A wide range for protocols for the acquisition and transmission of wired and wireless data

- Total flexibility: a fully open system that enables custom programming or easy, predefined configuration

- System adapted to the requirements of the railway sector

- Optimum cost solution

- Compliance with EN50155 and EN45545-2 standards

Safety Certified Products

INGESYS DCU SIL2

Railway Door controller with SIL2 certification

Our clients

Wiener Linien

Alstom

Pesa

Talgo

Features

- Door controller with High safety integrity level – SIL 2

- Distributed VCU

- Internally modular system customized to application requirements

- Wide range of I/Os and Communications modules (CAN, TRDP, TCP/IP, TCN, RS232/RS485, Modbus RTU / TCPIP, FTP, WebServices, SNTP ...)

- Designed in accordance with cybersecurity standards (IEC 62443)

- IEC61131, “C++”, Matlab/Simulink programmable -EN50155 & EN45545-2 compliant

- Embedded Web Server

Success stories

TCMS for Shunting Locomotives - Tülomsas (Turkey)

Toilet Module Controllers for High-Speed Trains - Alstom (USA)

Frequently Asked Questions

Do the devices comply with railway regulations?

Yes, all our PLCs comply with EN50155 standards (electromagnetic compatibility, temperature, vibrations, etc.) and EN45545-2 (fire protection), ensuring their use in demanding railway environments.

What input and output options do they offer?

We offer a wide range of digital and analogue I/O configurations, allowing flexibility to adapt to different railway applications.

In which languages can they be programmed?

They can be programmed in IEC 61131-3 (standard industrial automation language) and/or C++, allowing flexibility and compatibility with multiple development systems.

What is the supply guarantee for the devices?

We guarantee a supply of up to 30 years, ensuring long-term availability for railway projects with extended life cycles.

Do they include cybersecurity measures?

Yes, they comply with IEC62443 standards, ensuring advanced protection against unauthorised access and network vulnerabilities.

Which communication protocols do they support?

They are compatible with major railway communication protocols such as WTB, MVB, CAN, Ethernet, TRDP, PROFINET, RS485, among others.

Can they be integrated into different railway systems?

Yes, thanks to their compatibility with multiple communication protocols and the ability to customise the I/O configuration, they can be integrated into central control systems (TCMS), subsystem control (HVAC, doors, WC), and monitoring solutions.

Do the devices have functional safety certifications?

Yes, our door control devices are SIL 2 certified and comply with EN 50155 and EN 45545-2 standards, ensuring their reliability and safety in railway environments.