Power That Wins Projects

INGECON H2 MEGALYZER

Ingeteam’s modular, efficient and grid-ready rectifiers for electrolyzers

Ingeteam delivers the power to win projects — with modular, efficient, and grid-compliant solutions built to simplify integration, minimize risk, and meet the demands of the hydrogen sector today and tomorrow.

- 600+ MW delivered worldwide

- Advanced IGBT technology

- For all electrolyzer technologies — PEM, Alkaline, SOEC, and AEM

- Dual Expertise: Renewable Scale + Industrial Flexibility

- End-to-end support

Product Benefits

Maximum Efficiency & Competitive LCoH

- Optimized topology and control for maximum efficiency

- No external capacitors, filters, or STATCOMs needed — a complete plug-and-play solution

- Modular design lowers OPEX and engineering costs by simplifying integration and maintenance

Grid Compliant & Future-Proof

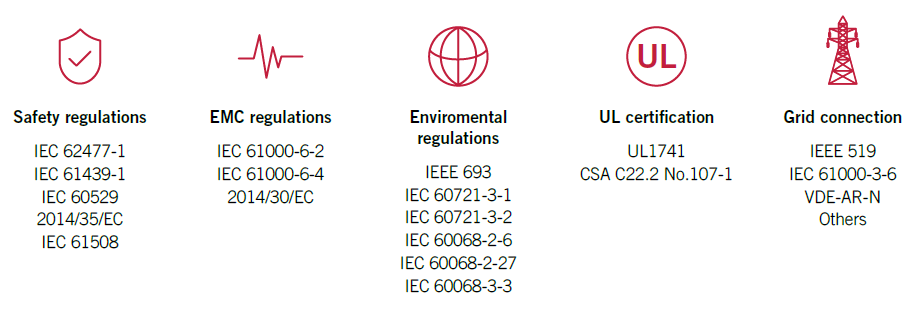

- Full compliance with current grid codes (RT, THD <5%, IEEE519, IEC61000-3-6)

- Supports evolving grid requirements including frequency and voltage support

- Controllable power factor and advanced grid support features enhance plant flexibility and stability

Reliability & Safety

- Degraded operation modes ensure uptime and availability

- Grid decoupling increases plant resilience and avoids overvoltage impacts

- Integrated safety features prioritize operator protection, with design enabling fast repairs and minimal civil works

Lowest Noise Levels

- Water-cooled design ensures optimal thermal management

- Outdoor-rated IP65 design for versatile installation environments

- The quietest converter solution in the market, compliant with environmental noise regulations

Modular & Scalable Design

- Modular architecture of converter blocks up to 36 kA within the width of a standard container

- Unprecedented power density for IGBT technology

- Fast commissioning, easy transport and seamless integration thanks to standardized modules and a commissioning wizard

Downloads

Upcoming events

Frequently Asked Questions

How does the INGECON H2 Megalyzer help reduce project costs and risks?

Will the Megalyzer remain compatible with evolving grid requirements?

Yes. The Megalyzer is fully compliant with current international grid codes (IEEE, IEC, FRT, THD) and is engineered to adapt to future regulatory demands. Features like controllable power factor, voltage and frequency support, and updatable control algorithms keep projects grid-ready for decades.

Is the Megalyzer reliable enough for large-scale, long-term projects?

Absolutely. The system is designed for 24/7 operation, with integrated safety features, redundant modes for degraded operation, and fast repair capabilities. Its outdoor-rated IP65, water-cooled design ensures resilience in harsh environments, while proven Ingeteam expertise provides long-term reliability.

What makes the Megalyzer different from other rectifier solutions in the market?

Unlike traditional systems, the Megalyzer delivers unprecedented power density in IGBT technology, with up to 36 kA in a containerized format. Its modular blocks allow for easy scaling, while degraded operation modes and grid decoupling ensure maximum uptime. This makes it a safer, more competitive, and more flexible choice for hydrogen projects.

How does the Megalyzer contribute to lowering the Levelized Cost of Hydrogen (LCoH)?

Maximum efficiency through advanced control algorithms means less energy is wasted. Reduced auxiliary components lower both capital and maintenance costs. These factors combined help project developers and operators achieve a more competitive LCoH, making green hydrogen more bankable.

What support and documentation does Ingeteam provide for integration?

Ingeteam provides tailored technical packs, integration files, and product documentation. Our engineering support team assists with integration, commissioning, and after-sales service, ensuring smooth deployment and peace of mind throughout the project lifecycle.

About us

Ingeteam H₂ Systems is a dedicated business unit within Ingeteam, committed to powering the renewable hydrogen revolution through cutting-edge power conversion technologies. Leveraging more than 50 years of expertise in power electronics and renewable integration, we develop modular, high-performance rectifiers and turnkey power solutions designed to connect renewable electricity sources with all major electrolyzer technologies — PEM, Alkaline, SOEC, and AEM.

Our proven portfolio exceeds 600 MW of deployed rectifiers worldwide, supporting projects from pilot plants to utility-scale hydrogen hubs. Our solutions emphasize safety, efficiency, and grid code compliance, ensuring flexible integration with renewable generation and stable operation across various hydrogen technologies.

Supported by end-to-end engineering services — from pre-sales consultation to commissioning and lifecycle management — Ingeteam H₂ Systems empowers customers to accelerate their hydrogen projects confidently and reliably.